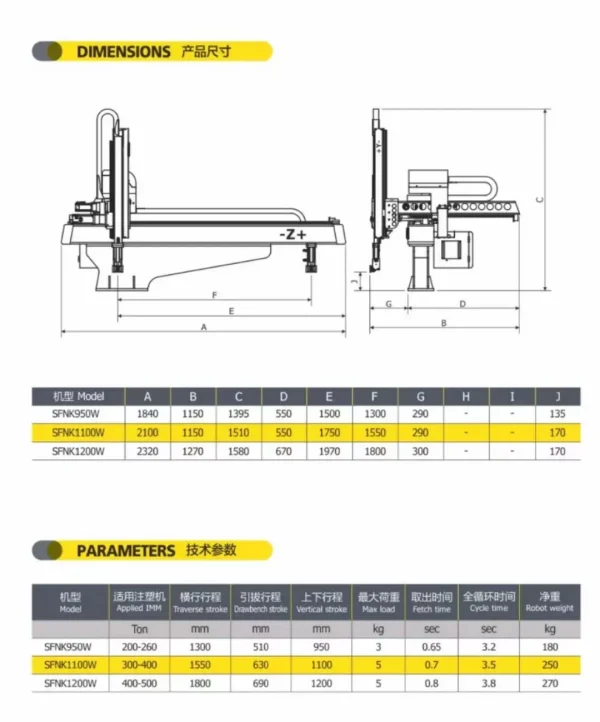

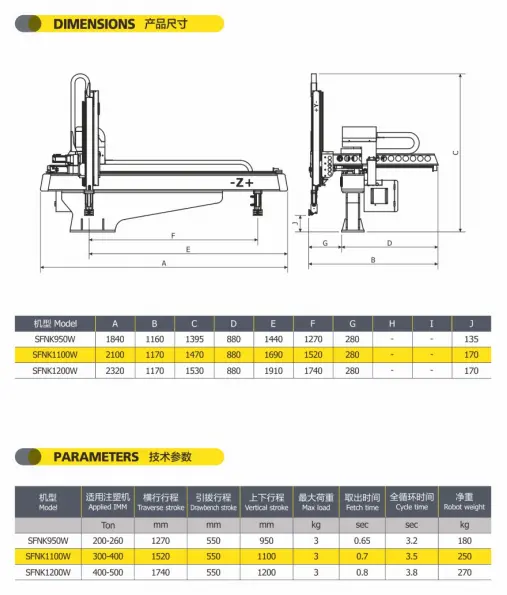

High Speed Robot SFNK Series

3-5 Axis Servo Injection Molding Robot

Single arm & Open type

Applied IMM:200-500T

Production cycle time:3-6secs

Certificate:ISO9001;CE Certification

100 sets of mold memory function;18 groups of standard programs;80 groups of user education programs

Share to:

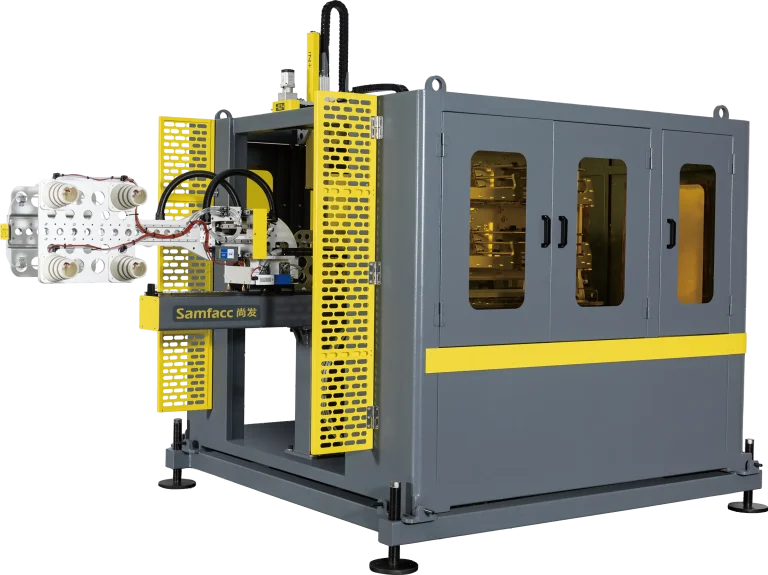

High-Speed 5 Axis Robot Arm for Precision and Efficiency

The Samfacc High-Speed Robot SFNK Series is a top-tier automation solution designed to meet the needs of industries where precision, speed, and reliability are critical. This model comes equipped with an advanced 5-axis robot arm, powered by servo robot technology, making it an ideal choice for applications like manufacturing, assembly, and material handling.

The Samfacc High-Speed Robot SFNK Series is a top-tier automation solution designed to meet the needs of industries where precision, speed, and reliability are critical. This model comes equipped with an advanced 5-axis robot arm, powered by servo robot technology, making it an ideal choice for applications like manufacturing, assembly, and material handling.

Key Features and Advantages:

- Precision with the 5 Axis Robot Arm: The SFNK series boasts a highly efficient 5-axis robot arm that offers exceptional flexibility and movement. This design enables the robot to handle complex tasks with high precision, perfect for industries such as electronics, automotive, and packaging, where accuracy is vital.

- Servo Robot Technology: Integrated servo robot technology provides smooth and accurate motion control, allowing the 5 axis robot arm to operate at impressive speeds without compromising accuracy. This results in faster cycle times, boosting productivity while maintaining consistent quality.

- Durable and Reliable Build: Crafted from high-quality materials, the 5 axis robot arm is designed for longevity, even in the toughest industrial settings. The servo robot system is built to require minimal maintenance, helping to reduce downtime and operational costs over the long term.

- Versatile Applications: The SFNK series is adaptable to a wide range of industrial tasks, from automated picking and placing to welding and material transfer. The flexibility provided by the 5 axis robot arm makes it a valuable asset to any production line, enhancing efficiency across different sectors.

- Energy Efficiency: Thanks to the advanced servo robot technology, this model operates efficiently, using less energy while maintaining high output. This not only helps lower operational costs but also supports more sustainable and environmentally friendly manufacturing processes.

FAQs:

Q1: What industries benefit most from the 5 axis robot arm?

Q1: What industries benefit most from the 5 axis robot arm?

A1: The 5 axis robot arm is particularly beneficial for industries that prioritize precision and speed, such as electronics manufacturing, automotive, and packaging.

Q2: How does servo robot technology boost efficiency?

A2: Servo robot technology ensures precise movement control, which leads to faster cycle times and reduces the likelihood of errors, ultimately improving overall efficiency.

Q3: Is the SFNK series easy to maintain?

A3: Yes, the servo robot system is designed for easy maintenance, requiring minimal effort while reducing downtime and keeping overall maintenance costs low.

By choosing the Samfacc High-Speed Robot SFNK Series, businesses can streamline their operations, cut costs, and improve product quality with the dependable performance of the 5 axis robot arm backed by servo robot technology.

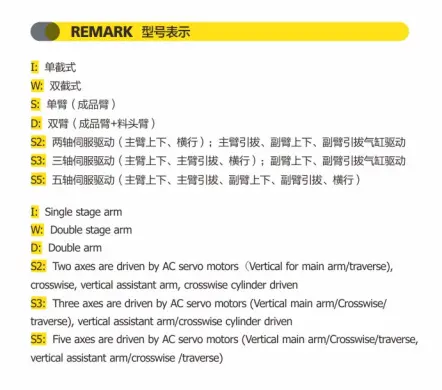

This series robot is a single arm with a double stage arm, The standard telescopic type is an open type and three to five axes servo system.

This open-type injection molding robot is a high-speed type, mainly for some products whose production cycle is between 3 to 6 seconds, such as disposable lunch boxes, knives, forks thin wall products, etc.

The fastest cycle time of a high-speed SFNK series robot can reach 2.8s, while the fetch time is 0.6s. As the featured product of Samfacc, this series has great advantages in the industry.

- Structure concept

High-speed series products are driven by servo motors, which greatly ensures the speed of operation. The open-type structure has good bearing capacity, which is suitable for multi-cavity products. The double-stage arm of the whole product adopts the principle of belt double-speed structure, which not only improves the running speed of the injection molding robot but also reduces requirements for the height of the workshop.

- User Friendly

The operating system of the high-speed robot is simple and convenient. Touch-screen intuitive operation, equipped with detailed user manuals and video guidance, you can learn it in the soonest half a day.

- Quality First

The lean assembly process has controlled the details and quality from the assembly stage. We have a professional quality management team, using scientific quality management standards, with advanced testing equipment, and strict control of the quality of robots, especially high-speed robots. All robots will test running for 24-36 hours before shipping.

- High Cost Effective

Robots assemble with high quality configuration parts imported from Japan, Germany, France, Taiwan…Samfacc has introduced international advanced CNC production equipment and built advanced automatic production lines to process the important robot parts, ensuring the accuracy of parts and smooth operation, the service life of the injection molding robots will be much longer.

- Better support

We provide detailed user manuals, program guidance videos, and process teaching PowerPoint files. More than 30 technicists to support the real-time technical guidance.

- Strong team

Hundreds of talents gathered together, we set product design, manufacture, sales, and after-service as one. Laid the foundation for the first-class Samfacc brand. Made unremitting efforts to create a cost-effective injection molding robot for the global market.